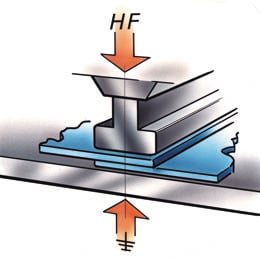

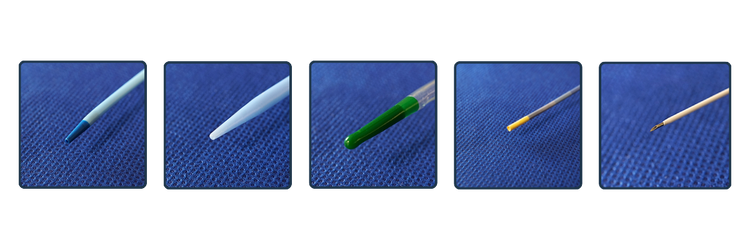

Over the past few years, we have stepped into designing and building automated assembly lines and shifted our focus to developing standard RF Welding and Catheter Tip-Forming equipment for the medical device manufacturing industry. Although we kept receiving customer requests for process automation, we kept our focus on developing new product lines to be the better choice in the technology field. Whether it's creating a custom automated assembly machine or integrating robotic cells with inspection systems, our commitment to meeting our clients' needs never wavers.

Recently, we had an opportunity to help a customer by introducing a robotic unload station on the ONEX Rotary RF welding system, which helped reduce one operator that was slowing down the process. The new modular solution, Robo-Flex Station, can be directly mounted onto our RF Sealing Press and programmed for component loading or unloading process. This modular solution is available in the market, helping our customers reduce labor costs and meet their cycle time requirements.

.gif?width=702&height=234&name=robotic%20welder%20gif%20(1).gif)

The success of this project underscores ONEX RF's dedication to innovation and customer satisfaction. By continuously adapting and introducing new solutions, ONEX RF reaffirms its position as a leader in RF welding and catheter Tip-Forming systems, meeting the latest trends of process automation and driving efficiency and reliability for its customers. Stay tuned for our new product lines coming soon.

Ready to witness our new Robo-Flex Stations on our Rotary RF Welders? Click here to watch the video.

Discover the capabilities of our RF Welders and range of RW welding dies.