RF Welding Solutions

Other Services:

- RF Welding Die Design and Fabrication

- Sample Runs for Evaluation

- Process Development

- Validation Support

Medical Device RF Sealing Essentials

Step by Step Guide for setting the RF welding process.

RF Welding or RF Heat Sealing is used for producing medical solution bags, collection or waste bags also air bladders, pressure or tourniquet cuffs.

Our focus on this page will be strictly for producing medical devices using the RF welding technology. You can use the same guidelines to RF seal other industrial products.

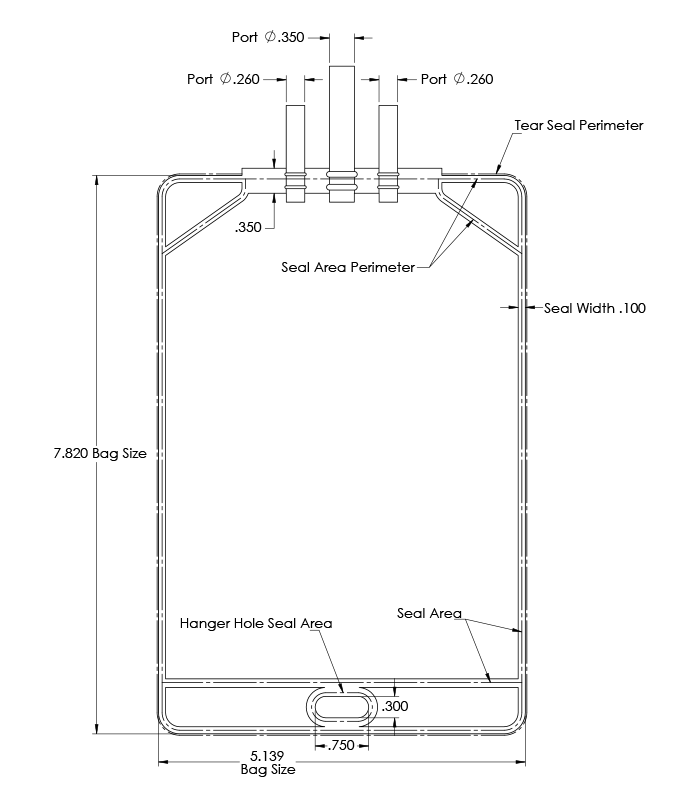

RF Power is direct proportional to the seal area. The seal area is the sum of all the areas of seal sections (Seal width multiplied by Seal length) AS=WS x LS.

Additional power is required for the products that require sealing plus cutting the perimeter using a tear seal blade.

The common practice for calculating the required RF power for tear seal is by multiplying the total seal length or the perimeter by 1/8. This will give you the equivalent seal area for the tear seal, which will be added to the perimeter seal area to calculate the total RF power.

Lets assume we want to make a flat seal of 1 square inch material and need to achieve good seal in 3 seconds.

As a general rule the RF power required for the materials below are:

PVC materials 250-300 watts

EVA materials 300-400 watts

TPU materials 400-500 watts

Applications notes:

RF Sealing Thin Materials: In a few applications where very thin TPU materials are used like 0.002" thick can be very difficult to seal. The material is so thin that the heat generated by the RF energy dissipates through the die immediately if proper insulator is not used. Thin material sealing will require extremely more power than above 4-5mil thick materials.

Heated Upper Platen (Die): It is recommended to heat the upper platen slightly higher then the room temperature and keep it constant. This practice helps achieving stable seal process because when the machine starts operating after several hours shut down, the die temperature is equal to the room temperature. After several RF cycles, as the material heats and cools, the die temperature slowly will rise due to residual heat build up, and will start melting the material faster. This condition can be controlled by using external thermal device to maintain constant temperature. Heated upper platen may also help reduce the overall cycle time and RF power.

RF Welding Large Product: When sealing large bladders the RF frequency become critical because of the 1/4 wave. The product must be smaller than the 1/4 wavelength of the frequency to prevent uneven potential difference in various section of the perimeter. Also the RF feed location into the upper platen may affect the even RF energy distribution across the product seal area. It is a common practice in the industry to use shims by lifting the die section to achieve the seal strength, which can be very time consuming process every time you change the setup. ONEX RF uses different type of RF feed line, which eliminates the need for shimming if the dies are correctly manufactures.

Process Tuning: Since ONEX RF uses hybrid generator, the ONEX RF welders come with Matching Network, which automatically matches the impedance when sealing the bag and the port in two cycles. This device also eliminates the possibility of process variations when RF welder requires multiple setups to run different size bags.

Because the port seal area is considerably smaller than the perimeter seal area, even though the auto tuner has the bandwidth to automatically match the difference ONEX RF may add a small inductor/capacitor network to better control the matching time.

Let's assume we are going to RF seal a 500ml PVC blood bag with 3 ports. When the process requires a tear seal we can not use any buffer material on top rather we will need a buffer material (Mylar) on the bottom of the bag so we can tear seal against it. (The thickness of the Mylar must be considered as overall die thickness to properly set the hard stops to control the final dept for tear seal blades. The blade must be parallel without any bumps or sharper edges to prevent arcing.

The bag will be RF sealed in 2 cycles:

Dual Cycle RF Sealing Switch: The ports and perimeters are RF sealed with a single die that has mandrels inside the ports (bushings). The RF energy is applied to the bag in two cycles through an RF Switch. The RF switch is a pneumatically activated mechanism that switches the RF signal from one side to another, let's temporary name them A and B. When sealing the ports the RF signal comes from the A connection and connects to the port sealing mandrel, the upper and lower dies are connected to ground. When RF energizes the the dielectric material clamped around the mandrel by the dies will start melting and bonding the bushing to the outer film top and bottom layers. After the Port RF seal cycle the RF Switch will energize the B side the RF power, while the die is closed, will apply to the upper die and A connection will not receive RF signal any more and bottom die will be connected to the ground. When RF signal is applied to the upper die the dielectric material, between the upper and lower dies, will melt and bond the perimeter of the bag.

Perimeter Seal Power: See the formula in the above section.

Port Sealing RF Power: Usually the RF power for sealing the ports is small like 100-150 watts, but because the RF energy is transferred through coax lines or mechanical connections, it causes energy losses (500w/12ft coax cable) thus it will require slightly higher power like 250-300 watts per port, higher power will help reduce the cycle time. Although high power shorter seal cycle may cause uneven seal thicknesses. It is critical to pay attention to even material flow to prevent any channel leaks around the ports.

Calculating RF Seal Power

Based on the RF Seal Area Calculations we need to multiply the total RF Seal area by 250 or 300 watts per square inch area.

The Perimeter RF Seal Power will be: 6.625 x 250 = 1.655 watts.

Ports RF Seal Power will be: 0.955 x 250 = 240 + 250 = 500 watts (add 250 watts for RF power losses).

When we start finding the process parameter, we always start in the manual screen because it's easier to quickly set the process parameters and make quick seals and see how the material behaves. The goal is to clamp the press and apply minimal RF power until it melts. When the material starts melting by keeping the RF power on for about 3-5 seconds the auto tuner will find the best tune point and capacitors will stop moving. We then use the capacitor values and set the initial set points by increasing the value by 5. Once the Tuning is set we can start playing with the parameters.

We load material and by using the manual station buttons.

RF Welding Cycle: The RF welder will start sealing the product and the RF power will turn energy Off after 5 seconds. We then manually retract the press and view the seal quality.

NOTE: The Manual Screen does not come with pre-seal cycle. Please make sure you use minimum 1-2 seconds ramp time allowing the RF energy gradually rise to the set power.

ONEX RF PC-HMI Manual Functions:

The manual screen is used for setting the RF sealing die, adjusting the hard stops and testing initial RF sealing process parameters.

RF Seal Observations:

As you will notice, we used 30% less power to make the first seal test. We usually do this to see if the die is applying even pressure. If, in the first cycle the ports are not sealed all the ways that will prevent the perimeter to seal on the port side. We can either increase the power until we achieve the correct port seal quality or we can only perform the perimeter seal without the ports to verify the die alignment and parallelism.

Even if the die is applying even pressure we may still notice some weak seal spots. the next step will be to increase power slowly another 250 watts or seal time 1 second to improve the seal quality.

ONEX RF welders are very easy to find the process parameter settings, because we only enter the power and time values on the HMI screen. The rest is controlled by the generator, which has closed loop power control and will give the exact power that was requested or set.

Adjusting Process Parameters: If we notice weak seal we start increasing power 100-250 watts at a time and repeat the process until we get good seal quality. If we notice over sealing like burning then we can reduce the time and power one parameter at a time.

After getting good seal quality: Once we get the product seal good, next we want to reduce the cycle time. By now we should have a feeling how the material behaves during each power increment. Let's reduce the cycle time to 3-4 seconds and increase power slowly until we get the same seal results with higher power.

Port Sealing Parameters: When using dual cycle seal process the manual screen will show the options to seal the ports and perimeters. You need to follow the same procedures to seal the the ports. First you need to find the capacitor tune points and later by slowly increasing the power optimize the port sealing parameters.

Insufficient RF Seal Power | Increase main seal RF power |

Insufficient RF Seal Time | Increase main seal time |

Insufficient Press Pressure | Increase seal pressure |

Hard Stops Too High | Remove or reduce the hard stop heights |

Insufficient Cool Time | Increase cool time |

Die Temperature Too Low | Make sure the die temperature is between 25-40°C. Note that some applications may require higher temperature. The most important thing is to keep the temperature constant. |

Die Surface Uneven or Not Parallel | If the weld peels in one section only measure die flatness and parallelism |

Hard Stops Uneven Heights | If the weld peels in one section only measure hard stops to make sure their heights are even |

Buffer Material Combination | Try different buffer material |

Insufficient RF Seal Power | Increase main seal RF power |

Insufficient RF Seal Time | Increase main seal time |

Insufficient Press Pressure | Increase seal pressure |

Die Surface Uneven or Not Parallel | If the weld peels in one section only measure die flatness and parallelism |

Hard Stops Uneven Heights | If the weld peels in one section only measure hard stops to make sure their heights are even |

Insufficient RF Seal Power | Increase main seal RF power |

Insufficient RF Seal Time | Increase main seal time |

Insufficient Press Pressure | Increase seal pressure |

Insufficient Cool Time | Increase cool time |

Die Temperature Too Low | Make sure the die temperature is between 25-40°C. Note that some applications may require higher temperature. The most important thing is to keep the temperature constant. |

Buffer Material Combination | Try different buffer material |

Too Much Press Pressure | Reduce seal pressure |

Die Temperature Too Low | Make sure the die temperature is between 25-40°C. Note that some applications may require higher temperature. The most important thing is to keep the temperature constant. |

Insufficient RF Seal Power | Increase main seal RF power |

Hard-Stops too short | Increase the hard stop height |

Press extend speed to high | Slow down the press coming down |

High RF Seal Power | Reduce main seal RF power |

High RF Seal Time | Reduce main seal time |

Insufficient Press Pressure | Increase seal pressure |

Hard Stops Too High | Remove or reduce the hard stop heights |

Insufficient Die-Material Contact | If the material is not touching as other areas the material temperature will increase and burn because it's not loosing heat through the die. |

High RF Seal Power | Reduce main seal RF power |

High RF Seal Time | Reduce main seal time |

Insufficient Die-Material Contact | If the material is not touching as other areas the material temperature will increase and burn because it's not loosing heat through the die. |

High RF Seal Power | Reduce main seal RF power |

Insufficient Press Pressure | Increase seal pressure |

Hard Stops Too High | Remove or reduce the hard stop heights |

Insufficient Die-Material Contact | If the material is not touching as other areas the material temperature will increase and burn because it's not loosing heat through the die. |

Uneven Die Surface Contact | Check the die surface for uneven sections |

For quick response, please provide details of your product, process needs, and full contact information.

For application related questions, you can always reach us by phone at +1(626)358-6639.

We offer excellent service:

We look forward to working with you soon.

EXPECT ONLY EXCELLENCE

ONEX RF Inc. is dedicated to giving you excellent service with quality results. Expect only excellence.

Copyright © 2020 ONEX RF . All rights reserved.Trademarks, including but not limited to ONEX RF Design are the trademarks or registered trademarks of ONEX RF and used under license by ONEX RF Based on mixed usage scenario.Terms of Use | Privacy Policy